The Metals & Minerals department comprises a team of specialists with extensive expertise of all industrial minerals, ferrous and non-ferrous metals.

The department offers a comprehensive service for the investigation of incidents and disputes involving the production, storage, transport and maritime trade of metals, metal products (e.g. pipes, drums, coils, bars, flats, plates), and minerals on an international basis.

Scope of work

Advice on metals and minerals storage, handling &

transportation

Assessment of environmental claims

Asset evaluation

Business Interruption assessment

Cargo disposal & damage mitigation

Cargo liquefaction studies

Cargo self-heating investigation

Environmental damage studies

Environmental impact studies

Expert

witness >

Feasibility studies

Independent sampling & assaying

Investigation of cargo damage incidents

Litigation

Live

attendance >

Load & discharge surveys

Market research

Mediation in trading disputes

Minerals plant analysis

Processing capabilities

Plant design and engineering

Post incident investigations >

Process analysis and value-in-use

Rapid response advisory service

Experts & Consultants

The Metals & Minerals department was established in 1994 and has an established track record of investigations into causation, advice on quantum and mitigation as well as risk management, safety and environmental studies.

The department is headed by Caline Sahyoun, who is supported by other specialist technical, engineering and trading consultants who have direct access to analytical and testing facilities at leading laboratories.

Member of the Institute of Materials, Minerals & Mining

Fellow of the Institute of Materials, Minerals & Mining

Professional Member of the Institute of Materials, Minerals and Mining since 1973

Chartered Engineer since 1978

He was appointed Technical Manager of the Engineering Materials Consultancy Service, University of Southampton in 1985 and has undertaken over 1,000 consultancies. These have included major investigations on high profile ship causalities where he has provided Expert Reports for London based solicitors on causalities.

Typical Cases

CWA has reviewed and reported on the arrangements for shipping and chartering world-wide and has been able to identify areas for substantial efficiency improvement.

CWA provides expert evidence on the technical and commercial aspects involving disputes arising from shipments of rolled coils.

CWA has been involved with the research into the root causes of self-heating of Direct Reduced Iron in the light of recurring problems in DRI shipments.

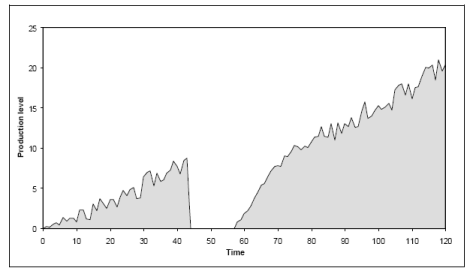

CWA has been involved in investigating business interruption (BI) incidents involving continuous process plants. CWA has reviewed the standard methodologies for ramp-up business interruption claims and evaluated the business interruption quantum for plants during start up.

CWA has investigated and advised on numerous incidents concerning the liquefaction of bulk solid cargoes including coal, iron ore fines, nickel laterite ores, and base metal concentrates.

In the light of these experiences, CWA have been involved in reviewing shipping procedures.

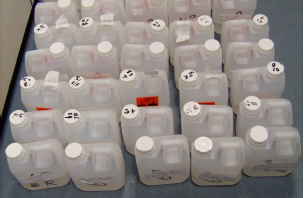

CWA has frequently advised on the treatment of a comprehensive range of contaminated cargoes and undertaken forensic analysis of the causes of contamination, often with support on the commercial front by assisting in disposing off-specification cargoes.

CWA provides expertise on the effects of long term storage of mineral concentrates required by, for example, the grounding of a bulk carrier which necessitated length repairs.

CWA was directed to inspect a cargo of potash which, on arrival showed evidence of water ingress. CWA was involved in the loss mitigation and arranged for the material to be treated locally.

CWA regularly provides expert advice either in situ or post incident for disputes arising during international maritime trade

Cargoes

The group provides expertise in all metals and mineral materials shipped worldwide.

Aluminium

Bauxite

Borax

Calcined Alumina

Calcined Brucite

Calcined Bauxite

Cement

Cement clinker

Clay

Clinker

Columbite concentrate

Coal

Copper

Etibor-48

Ferro Manganese

Ferro Silicon

Ferrovanadium

Fertiliser

Fluorspar

Glass Sand

Iron

Lead concentrates

Magnesite

Manganese ore

Molybdenum concentrates

Nickel laterite ore

Precious metals scrap

Pyritic ash

Pyrite concentrate